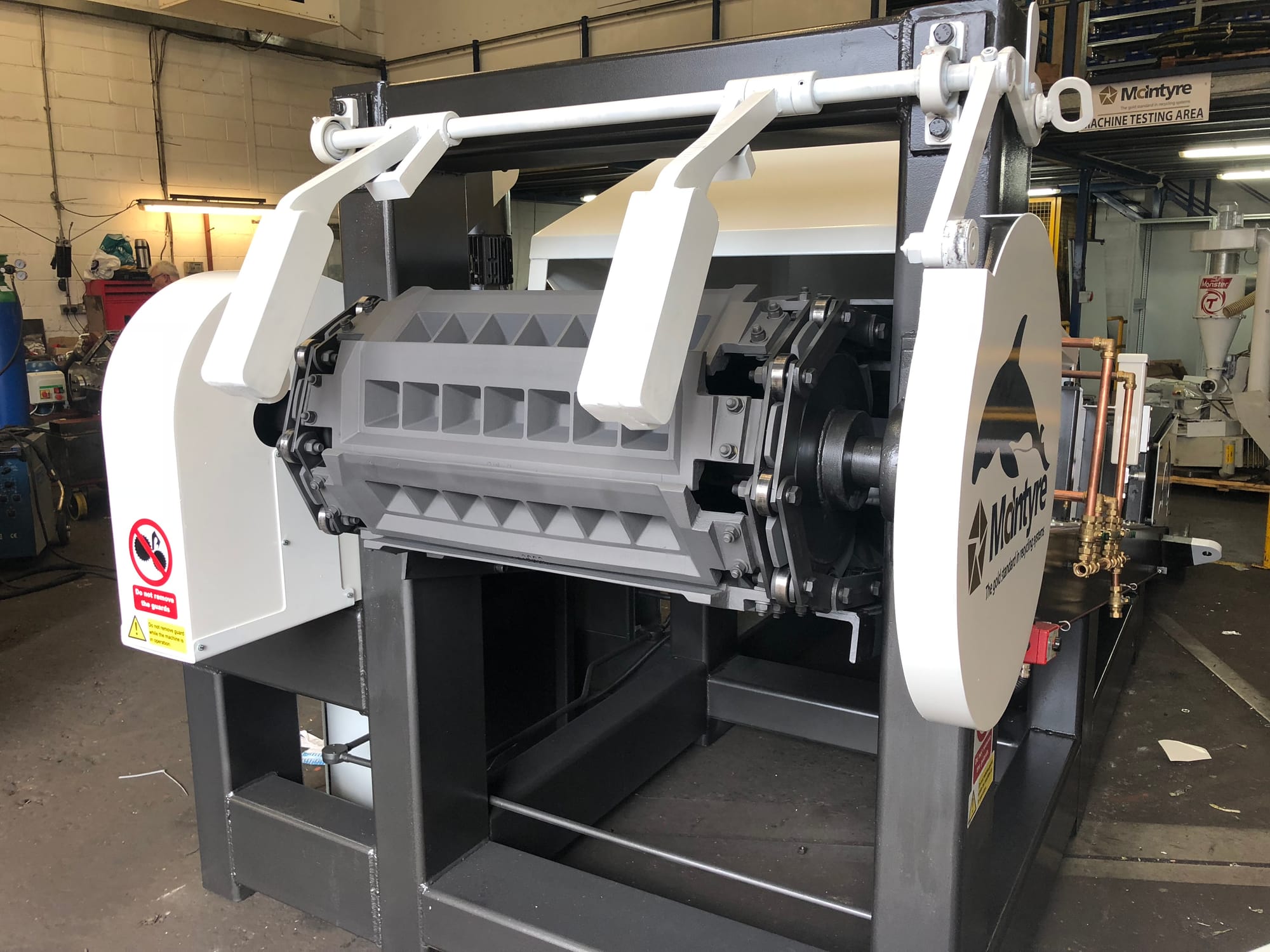

McIntyre Dolphin Casting Machine

McIntyre Dolphin Casting Machine

Technical Data

| Mould Type: | Cubes or ingots |

| Number of Moulds: | 56 Moulds |

| Number of Impressions: | Variable |

| Mould Material: | Ductile Cast Iron |

| Production Rate: | Up to 3 Tones per hour |

| Mould Pre-heat: | Natural gas burners (Gas regulator required) Total heat output = 50kw |

| Required gas pressure: | 10 – 20bar |

| Mould Cooling: | 24 Water Spray nozzles |

| Ingot Knockout: | Automatic hammer |

| Maximum Water consumption: | 120 Liters / min. at 3 bar |

| Pouring System: | Pouring Wheel |

| Drive Motor: | 1.1W 380-415V 50Hz 3 phase motor- gearbox variator |

| Speed control: | Electronic Inverter |

| Conveyor chain: | 160mm pitch bolt assembly |

| Machine construction: | Robust Steel frame – fully welded construction |

| Safety features: | Emergency stop switch |

| Additional Extras: | Oil pots for chain lubrication, Pre-Heat burners, flame failure detection & electronic ignition |

| Dimensions: | TBC |

| Approx. Weight: | Up to 6,500kg with Moulds |

Request a quote?

Please contact us to get a free quote!